SolidTech Workshops Tour

Issued by SolidTech Casting & Machining Department

General casting process includes product/molds design, molds making, casting, process quality checking, heat treatment (if needed), shot blasting, CNC machining, surface treatment, inspection and packing. Below we would like to introduce our facilities and producing process in detail.

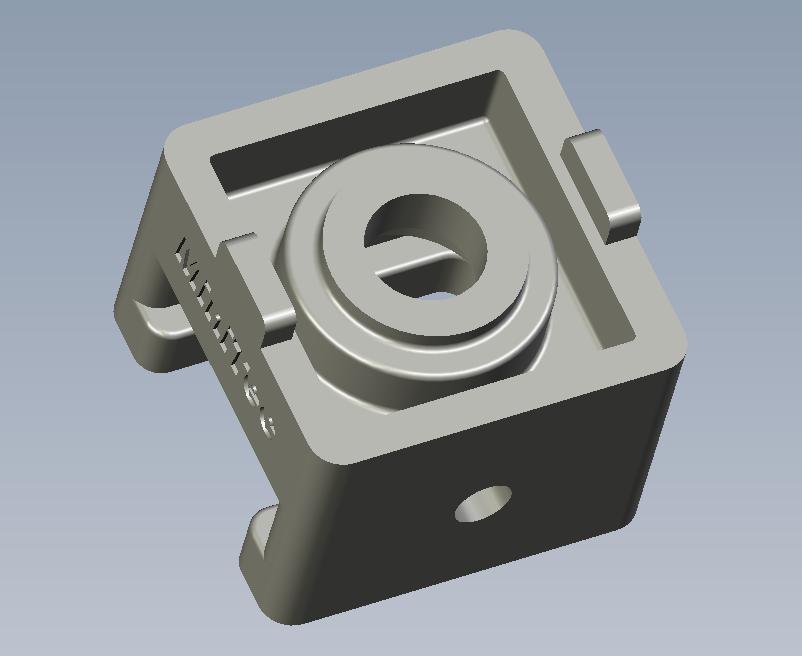

Product/Mold Design:

ODM/OEM products are highly welcome, and SolidTech is with 20 years’ experience in ODM/OEM market.

All kinds of drawings are available, such as dwg, pdf, jpg, stp, igs and etc.

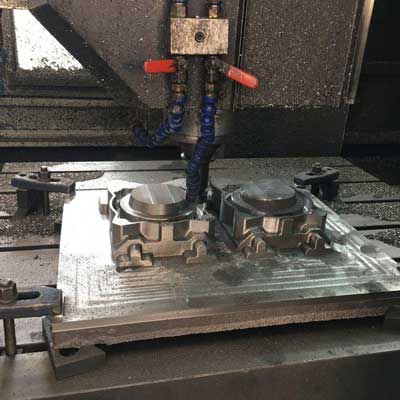

Molds Making:

In order to ensure lead time and quality, all the molds will be made in our CNC machining workshop.

Automatic Molding Line:

In 2016, we installed a fully automatic molding line imported from Japan, which highly improved surface quality and leveled our capacity for casting.

Manual Casting by Experienced Workers:

Our workers are full of experience and operate every process very carefully.

Heat Treatment:

Some castings need to be heat treated to get better and stable structure.

CNC Machining Workshop:

SolidTech has 12 sets of CNC Machining Center and 20 sets of CNC lathes, and could ensure 0.01-0.02mm tolerance depending on products design, size and raw material.